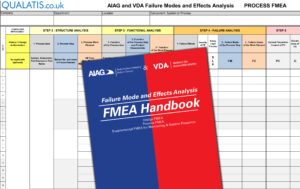

Failure Mode and Effects Analysis AIAG VDA Method

This course covers the needs and expectations of failure modes and effects analysis (FMEA) in line within the requirements of IATF 16949. Both process and design FMEA's can be covered using the FMEA AIAG VDA Guidance Manual 1st Issue. Using a case study or your organisations real products and processes the delegate can work through constructing a DFMEA (Design failure modes and effects analysis) or a PFMEA (Process failure modes and effects analysis).

Content:

The need for FMEA in process and product design

FMEA AIAG VDA objectives

The AIAG 4th edition handbook and key differences of the new FMEA VDA AIAG 1st edition handbook

The seven step FMEA process:

- Planning & Preparation

- Structure Analysis

- Function Analysis

- Failure Analysis

- Risk Analysis

- Optimization

- Results Documentation

Process (PFMEA) and Design (DFMEA) scoring and action priority

What does IATF 16949 say about FMEA?

Well... there are 23 mentions of FMEA in the standard so it's quite an important tool to implement effectively; something the IATF auditor will definitely be assessing the FMEA's.

Some of the IATF 16949 clause requirements that mention FMEA:

- 4.4.1.2 Special approval for Product Safety FMEA controls

- 7.2.3 Internal Auditors shall understand FMEA

- 8.3.2.1 Design and development planning review of FMEA

- 8.3. Document special characteristics on the FMEA

- 8.3.5.1 Product design outputs - DFMEA

- 8.3.5.2 Manufacturing process design output - PFMEA

- 8.5.1.1 Control plan – FMEA outputs

- 8.5.6.1.1 Risk analysis of temporary process controls

- 8.7.1.4 Risk analysis for repair of products

- 9.1.1.1 Verify that PFMEA is adhered to

- 9.1.1.2 Using FMEA to identify the use of statistical tools

- 9.2.2.3 Process audit to verify FMEA implementation

- 9.3.2.1 Management review of potential field failures

- 10.2.3 Update FMEA after corrective actions are taken

- 10.2.4 Use of FMEA to identify areas for error proofing

- 10.3.1 Continual improvement through risk reduction

Duration:

- 0.5 Day for Overview (normally online or combined with other core tools training)

- 1 day for PFMEA

- 1 day for DFMEA

- or 2 days for PFMEA and DFMEA

Available as an in-company or online course.